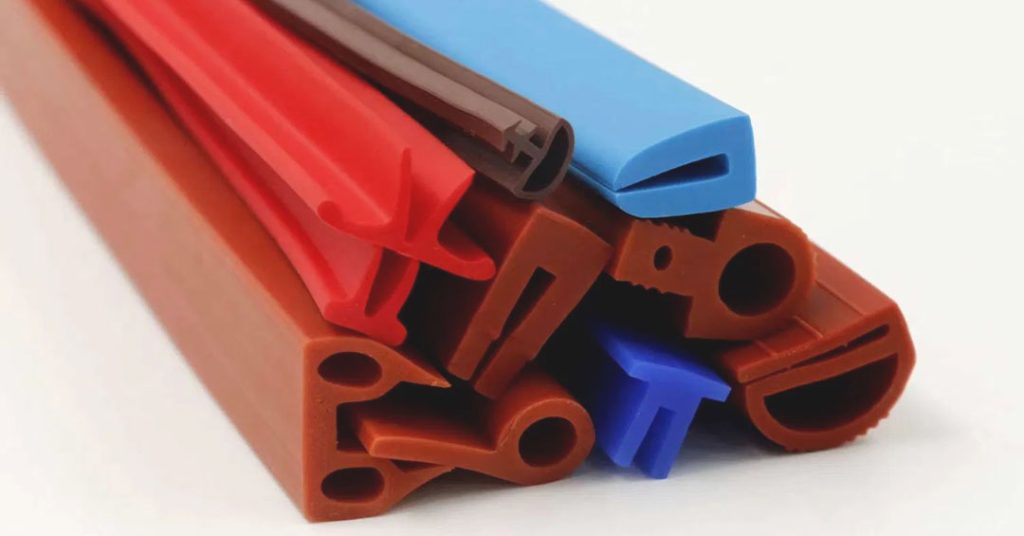

Silicone extrusion tubing has become a versatile and essential component across multiple industries due to its unique properties. From medical devices to industrial applications, this flexible and durable material is widely used. Let’s explore its diverse applications and understand why silicone tubing is so popular.

Characteristics and Advantages of Silicone Extrusion Tubing

Before diving into its applications, it’s essential to understand the features that make silicone extrusion tubing stand out:

- Flexibility: Silicone tubing is highly flexible, making it easy to install in various setups.

- Temperature Resistance: It can withstand extreme temperatures, ranging from -60°C to 200°C, without losing its properties.

- Durability: Resistant to UV, ozone, and aging, silicone tubing has a long service life.

- Non-toxic and Safe: Many silicone tubes are food-grade and medical-grade, making them safe for sensitive uses.

- Chemical Resistance: Silicone tubing resists many chemicals, oils, and solvents, enhancing its durability in demanding environments.

Common Applications of Silicone Extrusion Tubing

- Medical and Healthcare Industry

Silicone tubing is widely used in medical devices and applications, including:- IV drips and fluid delivery systems.

- Catheters and drainage tubes.

- Seals and gaskets for medical equipment.

Its biocompatibility and ability to handle sterilization processes make it ideal for healthcare needs.

- Food and Beverage Industry

Food-grade silicone tubing is used for:- Transferring liquids in beverage dispensing machines.

- Seals and gaskets in food processing equipment.

- Piping for dairy or brewery operations.

Silicone’s non-toxic nature ensures the safety of food and beverages.

- Industrial Applications

In industrial settings, silicone extrusion tubing is valued for:- Transporting chemicals, oils, and gases.

- Electrical insulation for wiring and cables.

- Protective coverings for sensitive equipment.

- Automotive Industry

Silicone tubing plays a significant role in the automotive sector by:- Serving as coolant hoses and vacuum lines.

- Acting as seals and gaskets for engines.

Its heat resistance and durability are crucial for high-performance vehicles.

- Consumer Products

Everyday products also utilize silicone tubing, including:- Flexible tubing in household appliances.

- Protective tubing for electronics and gadgets.

- Aerospace and Defense

In high-demand environments, silicone tubing is used for:- Fluid transfer in aircraft and spacecraft.

- Sealing components in high-temperature zones.

Why Choose Silicone Extrusion Tubing?

The versatility, safety, and durability of silicone extrusion tubing make it a go-to choice for various industries. Whether it’s for medical devices, industrial operations, or everyday consumer goods, silicone tubing delivers unparalleled performance.

Why Choose Us as Your Silicone Tubing Supplier?

Our factory stands out for the following reasons:

- Customization: We offer tailored solutions to meet specific industry needs, including size, shape, and grade.

- High-Quality Materials: Our silicone tubing is manufactured using premium, FDA-approved, and medical-grade silicone.

- Competitive Pricing: By optimizing production processes, we deliver high-quality products at affordable prices.

- Experienced Team: With years of expertise, we ensure consistency and quality in every product.

- Global Shipping: Our logistics network allows us to ship products quickly and efficiently worldwide.

Conclusion

Silicone extrusion tubing is a vital component in many industries, thanks to its unmatched flexibility, safety, and resistance to challenging conditions. With applications ranging from medical devices to industrial systems, it’s a material you can rely on. If you’re looking for a trusted supplier of silicone tubing, contact us today for top-notch solutions.

Optimize your operations with reliable silicone tubing—crafted to perfection!