Extruded silicone tubing is a versatile and reliable material widely used across various industries due to its excellent properties. Whether you are in manufacturing, healthcare, or automotive, this durable tubing solution offers unique advantages that make it essential for many applications.

What is Extruded Silicone Tubing?

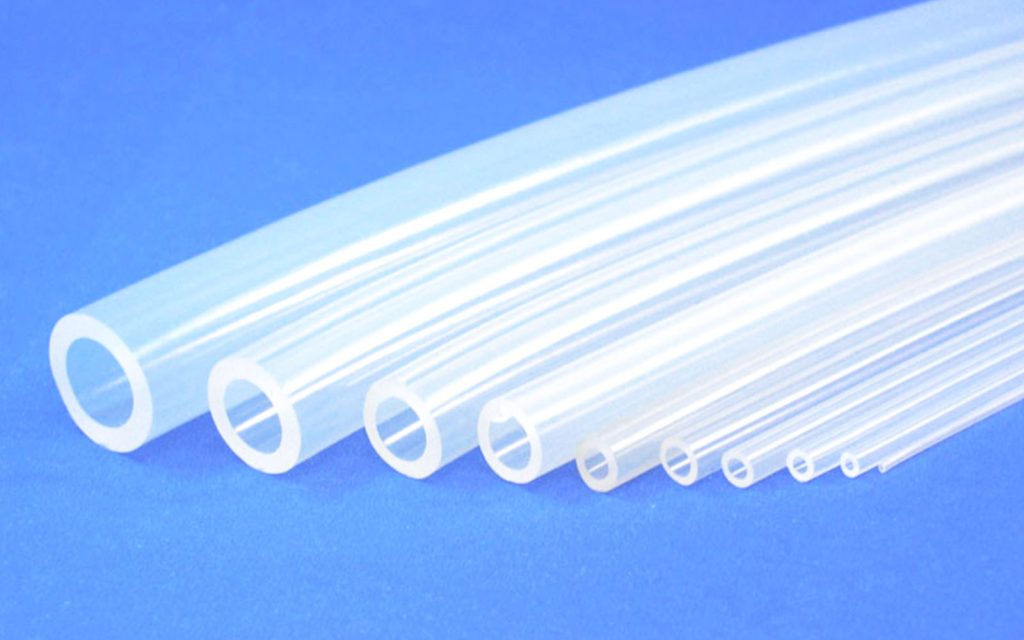

Extruded silicone tubing is produced by forcing silicone rubber through a mold to create continuous shapes of desired diameters and lengths. This process ensures uniformity, flexibility, and precision, making it ideal for both industrial and consumer applications.

Advantages of Extruded Silicone Tubing

- High Temperature Resistance:

Extruded silicone tubing can withstand extreme temperatures, ranging from -60°C to 250°C. This makes it suitable for applications in industries that deal with heat, such as automotive, electronics, and food processing. - Flexibility and Durability:

Silicone tubing is incredibly flexible, offering excellent bend radius without kinking. It’s also resistant to aging, UV radiation, and ozone, ensuring long-term performance even in harsh environments. - Non-Toxic and Biocompatible:

Made from non-toxic materials, extruded silicone tubing is safe for use in food and medical applications. It’s also biocompatible, making it suitable for medical devices and systems in the healthcare industry. - Chemical and Weather Resistance:

This tubing is highly resistant to a wide range of chemicals, oils, and solvents, ensuring longevity in industrial settings. It is also resistant to weathering, making it ideal for outdoor use. - Excellent Insulation Properties:

Silicone tubing provides superior electrical insulation, making it an ideal choice for wiring and cable applications in electronics and electrical engineering. - Customizable:

Extruded silicone tubing can be manufactured in various colors, diameters, and wall thicknesses, allowing for customized solutions to meet specific project needs.

Applications of Extruded Silicone Tubing

- Medical and Healthcare:

Extruded silicone tubing is commonly used in medical devices, including catheters, respiratory tubes, and drainage tubes. Its biocompatibility, non-toxicity, and flexibility make it safe for prolonged contact with the human body. - Food and Beverage:

In the food industry, silicone tubing is used for transferring liquids, food processing, and in appliances such as milk lines, beverage dispensers, and dispensers in commercial kitchens. Its resistance to high temperatures ensures food safety. - Electronics:

Silicone tubing is widely used in the electronics industry for insulating wires and cables, protecting components from heat, moisture, and mechanical wear. - Automotive Industry:

Due to its high-temperature resistance, silicone tubing is used in automotive applications such as coolant hoses, vacuum hoses, and other automotive systems that need to withstand high temperatures and chemicals. - Consumer Products:

Silicone tubing is used in various consumer products like straws, water bottles, baby products, and more. Its non-toxic nature and durability make it an excellent choice for everyday items. - Industrial Applications:

From oil and gas pipelines to laboratory equipment, extruded silicone tubing provides reliable, high-performance solutions in many industrial sectors.

Why Choose Our Silicone Tubing?

At Linze Times, we offer high-quality extruded silicone tubing made to meet the most stringent standards. With a focus on precision and durability, our products are engineered to provide reliable performance across a wide range of applications. Whether you need standard or custom tubing solutions, we can meet your specifications and provide flexible manufacturing options.

Conclusion

Extruded silicone tubing offers a range of benefits including flexibility, high temperature resistance, and chemical stability, making it ideal for a wide array of applications. From the medical and food industries to electronics and automotive sectors, this versatile material helps ensure safety, durability, and efficiency.

Interested in learning more about our extruded silicone tubing? Contact us today to discuss your requirements and discover how we can help with your next project.